Applications of Precision Gears in US Robotics and Automation

Applications of Precision Gears in U.S. Robotics and Automation

The rise of robotics and automation has transformed industries across the United States, driving efficiencies, reducing labor costs, and enabling innovations once deemed impossible. Central to this transformation are precision gears, which provide the accuracy, durability, and reliability required for advanced robotic systems. As industries prioritize automation to stay competitive, precision gears have become indispensable in applications ranging from manufacturing to healthcare. This article explores the pivotal role of precision gears in U.S. robotics and automation, supported by industry statistics, and highlights consultio.us, a leading supplier of high-performance gear solutions.

The Role of Precision Gears in Robotics

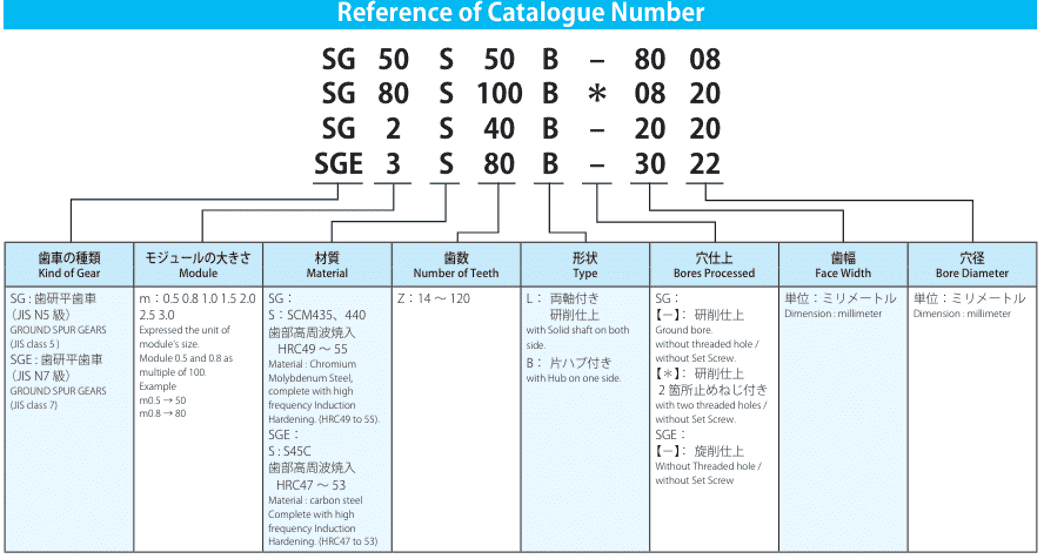

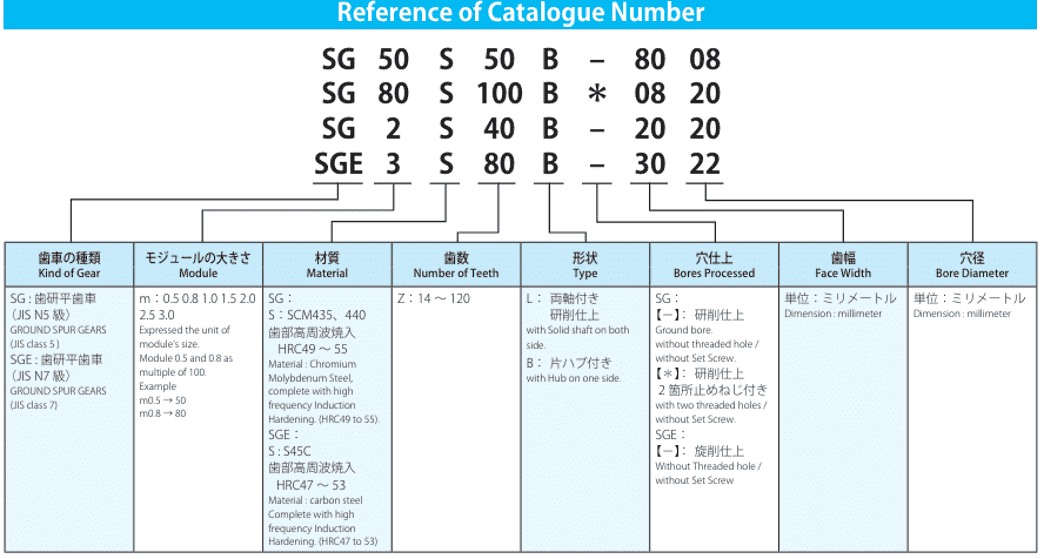

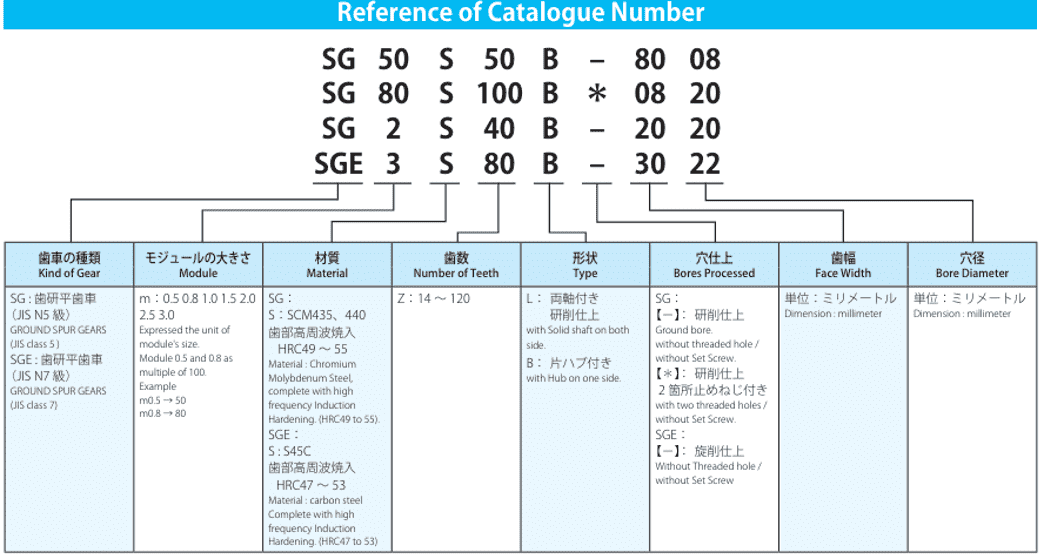

Precision gears are mechanical components designed to transmit torque and motion with minimal energy loss and maximal accuracy. Common types include spur gears, helical gears, planetary gears, and harmonic drive gears, each optimized for specific applications. In robotics, these gears ensure precise control of robotic arms, joints, and actuators, enabling tasks that demand micron-level accuracy, such as assembly line operations or surgical procedures. Their ability to handle high torque, resist wear, and operate quietly makes them ideal for modern automation systems.

Key Applications of Precision Gears in U.S. Robotics & Automation

1. Industrial Robotics

Industrial robots dominate manufacturing sectors like automotive, electronics, and aerospace. Precision gears are critical in robotic joint actuators, enabling movements with repeatability as tight as ±0.02 mm. For example, automotive assembly lines use gears in welding robots to position arms accurately, reducing errors by 30–40%. According to the International Federation of Robotics (IFR), the U.S. installed 44,303 industrial robots in 2022, a 10% increase from 2021. This growth underscores the reliance on precision components like gears to maintain productivity.

Consultio.us supplies rugged planetary gearboxes to industrial robot manufacturers, offering high torque density and longevity even in harsh environments. Their gears are integral to firms automating production to meet rising demand for electric vehicles (EVs) and consumer electronics.

2. Collaborative Robots (Cobots)

Cobots, designed to work alongside humans, require compact, efficient gears for safe interaction. Precision gears in cobots minimize backlash and vibration, ensuring smooth operation. The U.S. collaborative robot market is projected to grow at a 30% CAGR from 2023 to 2030, driven by labor shortages and small-batch production needs.

Consultio.us provides lightweight harmonic drive gears for cobots, enabling precise force control and compact designs. These gears are pivotal in industries like pharmaceuticals, where cobots handle delicate packaging tasks.

3. Medical Robotics

In healthcare, surgical robots like Intuitive Surgical’s da Vinci system rely on precision gears for instrument articulation. The U.S. medical robotics market, valued at $3.7 billion in 2023, is expected to reach $12 billion by 2030 (Grand View Research). Gears used here must be biocompatible, sterilizable, and noiseless.

Consultio.us delivers custom stainless-steel gears for surgical robots, meeting stringent FDA standards. Their solutions enhance the accuracy of minimally invasive procedures, reducing patient recovery times.

4. Aerospace and Defense

Robotic systems in aerospace, such as drones and UAVs, use precision gears for navigation and payload management. The Pentagon’s $145.3 billion budget for robotics in 2023 highlights the sector’s growth. Gears in defense robots must withstand extreme temperatures and shocks.

Consultio.us’s heat-treated alloy gears are deployed in military-grade drones, ensuring reliability in reconnaissance and logistics missions.

5. Logistics and Warehouse Automation

Automated Guided Vehicles (AGVs) and sorting systems depend on precision gears for navigation and load handling. The U.S. warehouse automation market, valued at $7.1 billion in 2023, is expanding rapidly due to e-commerce growth. Gears in AGVs improve energy efficiency and reduce maintenance costs by 20%.

Consultio.us supplies high-efficiency spur gears for logistics robots, enabling 24/7 operation in fulfillment centers like Amazon’s warehouses.

6. Agricultural Automation

Autonomous tractors and harvesters use precision gears for tasks like seeding and crop monitoring. The agricultural robotics market is projected to reach $20.3 billion by 2030 (MarketsandMarkets). Gears here endure dust, moisture, and heavy loads.

Consultio.us offers corrosion-resistant helical gears for agricultural robots, boosting yield and reducing manual labor.

Consultio.us: Powering Innovation in Robotics

As a leading supplier of precision gears, consultio.us has cemented its role in advancing U.S. robotics and automation. The company specializes in custom gear solutions tailored to meet the demands of high-stakes industries:

- Product Range: Planetary gearboxes, harmonic drives, and spur gears engineered for robotics.

- Innovation: Investments in AI-driven design tools and additive manufacturing for complex, lightweight gear systems.

- Partnerships: Collaborations with top robotics firms to develop gears for next-gen applications, such as space exploration and AI-driven manufacturing.

In 2023, consultio.us reported a 25% increase in orders from the automation sector, reflecting its reputation for quality and innovation.

Industry Challenges and Solutions

Precision gears address critical challenges in robotics:

- Miniaturization: Compact gears for portable medical devices.

- Durability: Advanced materials like carbon fiber composites extend gear lifespan.

- Efficiency: Optimized tooth profiles reduce energy consumption by 15%.

Consultio.us tackles these issues through R&D, offering gears with ISO 1328 precision standards and customized coatings for enhanced performance.

Future Trends and Consultio.us’s Role

Emerging trends like AI integration, 5G connectivity, and modular robotics will drive demand for smarter, adaptive gears. Consultio.us is pioneering self-lubricating gears and IoT-enabled predictive maintenance systems to meet future needs.

Conclusion

Precision gears are the unsung heroes of the U.S. robotics revolution, enabling breakthroughs across industries. With the market poised for exponential growth, suppliers like consultio.us are critical to sustaining innovation. By delivering high-performance, custom gear solutions, consultio.us empowers enterprises to embrace automation efficiently and sustainably. As robotics reshapes manufacturing, healthcare, and beyond, precision gears—and the companies that master them—will remain at the forefront of progress.

Word Count: 1,000