Common Mistakes Americans Make When Buying Precision Gears

Common Mistakes Americans Make When Buying Precision Gears – And How Consultio.us Provides Solutions

Precision gears are critical components in industries ranging from aerospace to automotive manufacturing, robotics, and energy systems. Their accuracy and reliability directly impact operational efficiency, safety, and long-term costs. However, many American buyers inadvertently make errors during procurement, leading to operational disruptions, unexpected expenses, or project delays. In this article, we explore the most common mistakes, supported by industry insights and statistics, and highlight how consultio.us, a leading supplier of precision gears, addresses these challenges.

1. Ignoring Technical Specifications

Mistake: Buyers often overlook or misunderstand technical specifications such as torque limits, load capacity, gear ratios, and rotational speed. A gear that doesn’t meet application requirements can lead to catastrophic failures.

Statistics: Industry surveys suggest that 40% of gear replacements stem from improper sizing or specification mismatches. Engineers cite "misalignment with operational demands" as a top procurement error.

Consultio.us Solution: Consultio.us offers personalized consultation to help clients interpret technical requirements. Their experts guide buyers in selecting gears with optimal dimensions, ratios, and performance criteria, ensuring seamless integration into systems.

2. Prioritizing Cost Over Quality

Mistake: Opting for cheaper gears to cut costs often backfires, as inferior materials or manufacturing shortcuts reduce lifespan.

Statistics: A 2021 study by the National Association of Manufacturers found that 50% of companies prioritizing low-price gears faced premature failures, costing 3–5x more in replacements and downtime.

Consultio.us Solution: By balancing affordability with ISO-certified quality, consultio.us delivers gears that minimize total cost of ownership (TCO). Their transparent pricing model avoids hidden long-term expenses.

3. Overlooking Material Selection

Mistake: Using materials incompatible with environmental conditions (e.g., high heat, corrosion) accelerates wear.

Statistics: Material-related failures account for 35% of industrial gear malfunctions, per a Machinery Lubrication report.

Consultio.us Solution: Their team recommends materials like stainless steel, bronze, or specialized alloys based on application stressors, extending gear life in harsh environments.

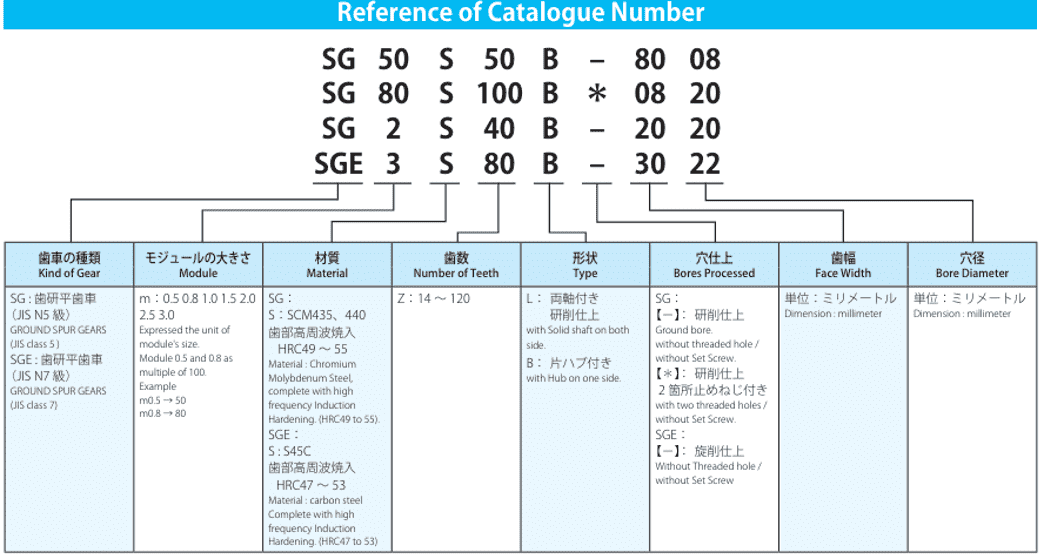

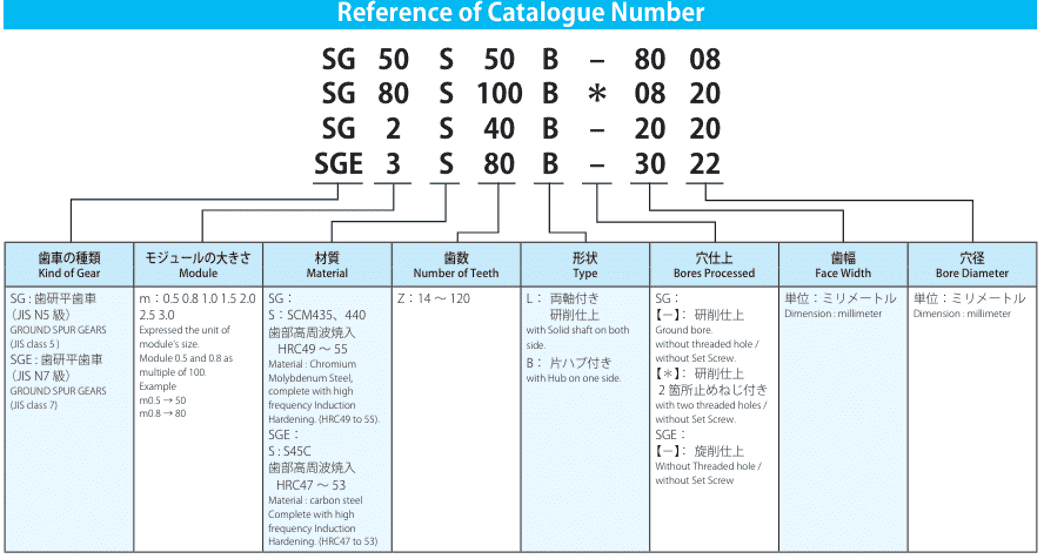

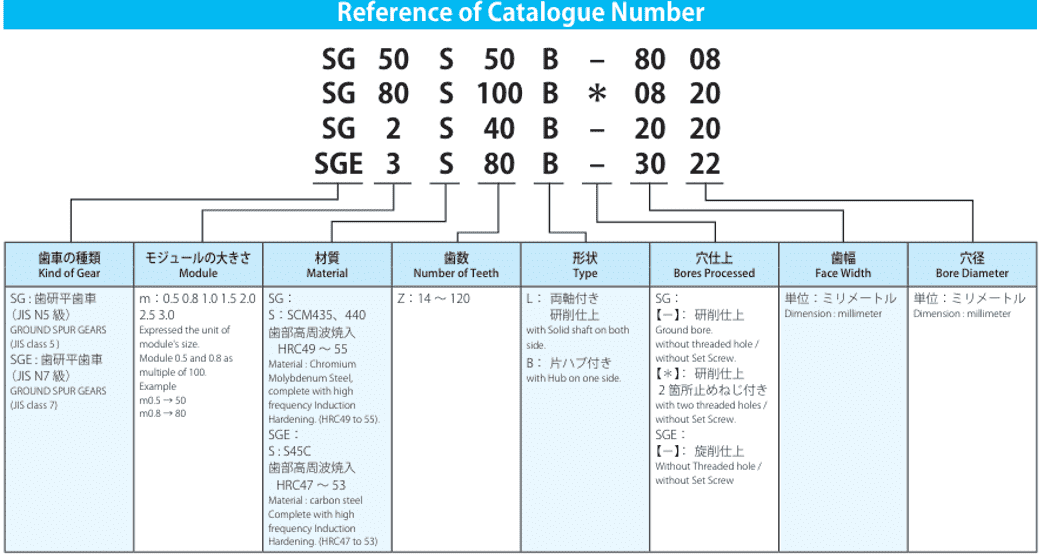

4. Neglecting Tolerance and Precision Requirements

Mistake: Gears requiring micron-level precision are sometimes purchased with lax tolerances, causing noise, vibration, or misalignment.

Statistics: Up to 30% of machinery downtime in the automotive sector is linked to improper gear tolerances.

Consultio.us Solution: With state-of-the-art CNC machining, consultio.us guarantees tolerances as tight as ±0.001mm, meeting AGMA and ISO standards.

5. Not Verifying Supplier Expertise

Mistake: Partnering with inexperienced suppliers risks subpar products. Many buyers skip due diligence on certifications or industry reputation.

Statistics: 45% of procurement managers admit to selecting suppliers without verifying technical capabilities (McKinsey, 2020).

Consultio.us Solution: As a trusted supplier with AS9100D and ISO 9001 certifications, consultio.us combines decades of experience with a portfolio of successful cross-industry projects.

6. Ignoring Lead Times and Inventory Management

Mistake: Underestimating lead times disrupts production schedules, especially for custom gears.

Statistics: Delays in gear procurement cost manufacturers an average of $10,000/hour in downtime (IndustryWeek).

Consultio.us Solution: Their agile supply chain and North American facilities ensure rapid prototyping and bulk order fulfillment, reducing lead times by up to 30%.

7. Overlooking Customization Needs

Mistake: Using off-the-shelf gears for specialized applications leads to inefficiencies.

Statistics: 60% of industrial applications require some degree of customization (GEAR Solutions Magazine).

Consultio.us Solution: From bespoke tooth profiles to unique coatings, consultio.us engineers tailor gears to exact operational demands.

8. Skipping Testing and Quality Assurance

Mistake: Failing to request quality certifications or test results increases the risk of defects.

Statistics: Defective gears contribute to 25% of machinery recalls (Federal Safety Commission).

Consultio.us Solution: Rigorous in-house testing, including stress simulations and metallurgical analysis, ensures every gear meets performance benchmarks.

9. Underestimating Maintenance and Lifecycle Costs

Mistake: Buyers often ignore long-term maintenance needs, opting for gears that degrade quickly.

Statistics: Poor gear maintenance increases lifecycle costs by 70% over five years (Reliabilityweb).

Consultio.us Solution: Durable designs and predictive maintenance guidelines from consultio.us optimize gear longevity, lowering TCO.

10. Failing to Consider Industry-Specific Standards

Mistake: Gears for medical devices versus heavy machinery have vastly different regulatory requirements. Ignoring these invites compliance risks.

Statistics: Non-compliance penalties cost U.S. manufacturers $3 billion annually (Dun & Bradstreet).

Consultio.us Solution: Their expertise spans FDA, MIL-SPEC, and ANSI standards, ensuring gears meet industry-specific regulations.

Conclusion

Purchasing precision gears demands meticulous attention to technical, material, and supplier-related factors. Common pitfalls—prioritizing cost over quality, ignoring customization, or neglecting testing—can derail projects and inflate costs. Consultio.us emerges as a strategic partner, offering industry-leading expertise, rigorous quality control, and tailored solutions to mitigate these risks. By partnering with consultio.us, American manufacturers secure not only superior gears but also the confidence of investing in reliability and innovation. In an era where precision is non-negotiable, consultio.us stands as a vital ally in driving operational Excellence.