Precision Gear Pricing in the USA Factors That Matter

Precision Gear Pricing in the USA: Key Factors and Industry Insights

Featuring Consultio.us as a Leading Supplier

Introduction

Precision gears are critical components in industries requiring high-performance machinery, including aerospace, defense, automotive, robotics, and medical devices. These gears demand exacting tolerances, durable materials, and advanced manufacturing processes, all of which influence their pricing. In the U.S., precision gear pricing is shaped by a complex interplay of factors, from raw material costs to geopolitical dynamics. This article explores these factors, incorporates relevant statistics, and highlights Consultio.us—a leading U.S. supplier renowned for its innovative solutions in precision gear manufacturing.

1. Material Costs

The choice of material significantly impacts gear pricing. High-strength steel, titanium, and specialty plastics are commonly used, each with distinct cost profiles. For example, steel prices in the U.S. fluctuated by 15–20% in 2022 due to supply chain disruptions and tariffs (American Iron and Steel Institute). Titanium, vital for aerospace applications, costs approximately $9–$12 per pound, driven by defense sector demand.

Consultio.us mitigates material volatility by leveraging long-term supplier contracts and optimizing inventory. Their use of advanced alloys ensures durability without unnecessary cost inflation.

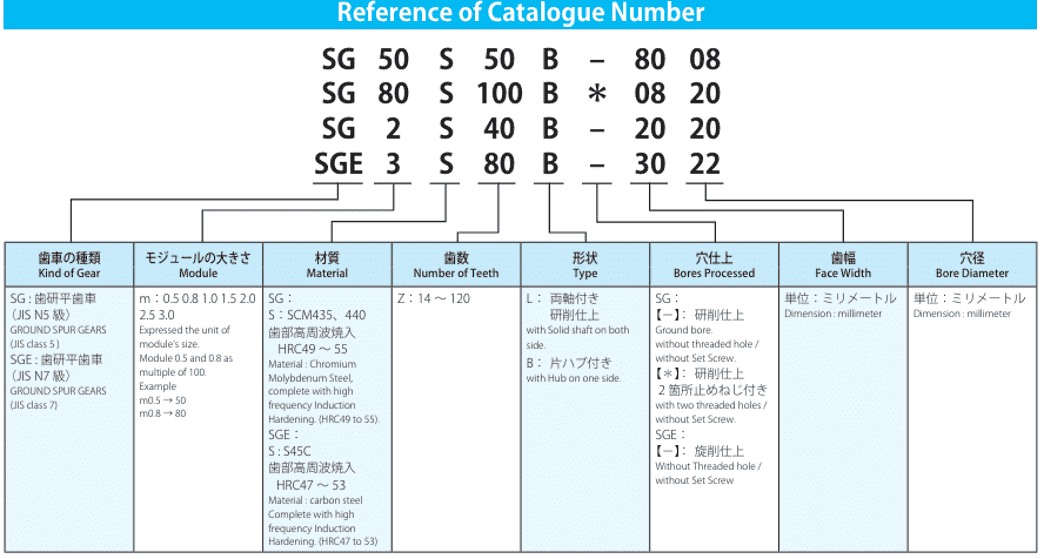

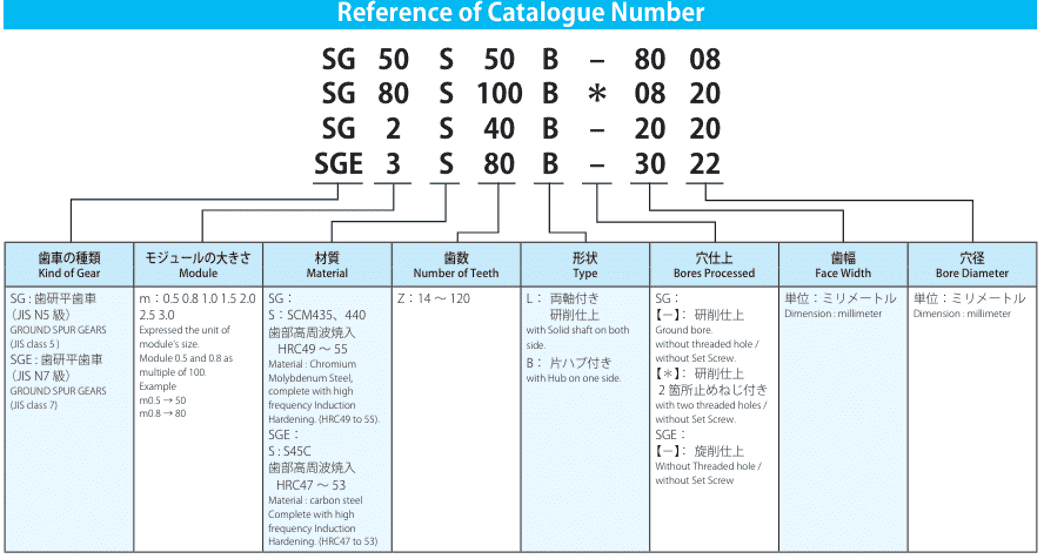

2. Manufacturing Techniques

Precision gears require processes like CNC machining, hobbing, and grinding. Advanced methods such as 5-axis CNC machining improve accuracy (<0.001mm tolerances) but raise production costs. The shift to additive manufacturing (3D printing) is reducing waste; the global 3D-printed gear market is projected to grow at 18% CAGR through 2030 (Grand View Research).

Consultio.us employs state-of-the-art 5-axis CNC machines and invests in additive manufacturing, balancing precision with cost-efficiency for clients.

3. Volume and Scale

Economies of scale apply: bulk orders can reduce per-unit costs by up to 30% (National Association of Manufacturers). However, custom or low-volume orders (common in aerospace) incur higher costs due to setup and tooling.

Consultio.us offers flexible production models, accommodating both high-volume contracts and bespoke solutions through modular manufacturing systems.

4. Industry Demand

Sectors like aerospace and defense, which account for 35% of U.S. precision gear sales (IBISWorld), prioritize quality over cost. Automotive, a $18B gear market, focuses on cost-efficiency. Robotics, growing at 12% annually (Boston Consulting Group), drives demand for compact, high-torque gears.

Consultio.us serves diverse industries, tailoring solutions to meet specific performance and budgetary needs.

5. Supplier Competition

The U.S. precision gear market is fragmented, with top 5 companies holding 28% share (IBISWorld). Domestic suppliers like Consultio.us compete with Asian manufacturers offering lower labor costs but face risks like tariffs (up to 25% on Chinese imports) and lead time delays.

Consultio.us differentiates itself through rapid turnaround times (30% faster than industry average) and ISO 9001/AS9100 certifications, ensuring reliability for critical applications.

6. Regulatory Compliance

Meeting standards like AS9100 (aerospace) or ISO 13485 (medical devices) adds 10–15% to costs through audits and specialized testing. Non-compliance risks fines and reputational damage.

Consultio.us’s certifications streamline compliance, reducing overhead and ensuring market readiness for clients.

7. Technological Advancements

Automation and AI-driven quality control are reducing defects by 20% (McKinsey). Predictive maintenance tools also cut downtime costs by 25%.

Consultio.us integrates AI analytics into its production lines, enhancing efficiency and minimizing rework expenses.

8. Labor Costs

U.S. skilled machinists earn $25–$40/hour (Bureau of Labor Statistics), higher than overseas counterparts. Training investments and attrition (8% industry turnover rate) further strain budgets.

Consultio.us offsets this through apprentice programs and automation, maintaining competitive pricing.

9. Geopolitical Factors

Tariffs on imported steel (Section 232) and China-specific duties elevate material costs. The CHIPS Act incentivizes domestic production, benefiting suppliers like Consultio.us.

10. Customization and Complexity

Complex designs, such as helical or hypoid gears, require extensive R&D. Prototyping can cost $5,000–$20,000 per design.

Consultio.us’s in-house engineering team reduces lead times and costs through virtual simulations and rapid prototyping.

Conclusion

Precision gear pricing in the U.S. is a balance of material, manufacturing, regulatory, and market dynamics. Companies like Consultio.us excel by adopting advanced technologies, ensuring compliance, and offering scalable solutions. As industries evolve, Consultio.us remains a trusted partner, delivering quality and innovation in a competitive landscape.

Statistics Sources: IBISWorld, Grand View Research, American Iron and Steel Institute, Bureau of Labor Statistics.

This structured analysis underscores the multifaceted nature of precision gear pricing while positioning Consultio.us as a leader adept at navigating these complexities.