Precision Gear Reverse Engineering Consultio US Services

Precision Gear Reverse Engineering Consultio US Services: Leading Innovation in Industrial Solutions

In the intricate world of mechanical engineering, precision gears are the unsung heroes of countless industries. From aerospace and automotive systems to energy production and defense machinery, gears ensure the seamless transfer of power and motion. However, when these critical components wear out or become obsolete, industries face costly downtime and operational challenges. This is where Precision Gear Reverse Engineering Consultio US Services steps in as a lifeline, offering state-of-the-art solutions to recreate, optimize, and innovate gear systems. As a leader in this specialized field, consultio.us has cemented its reputation by combining cutting-edge technology, technical expertise, and customer-centric approaches, positioning itself as the go-to supplier for precision gear reverse engineering in the U.S. and beyond.

The Critical Role of Gear Reverse Engineering

Reverse engineering involves deconstructing existing components to understand their design, materials, and functionality, enabling accurate replication or improvement. For precision gears—which demand micron-level accuracy—this process is both an art and a science. Aging machinery, discontinued parts, or the need for performance upgrades often drive industries to seek reverse engineering services. According to Grand View Research, the global reverse engineering market is projected to grow at a compound annual growth rate (CAGR) of 8.3% between 2021 and 2028, reflecting rising demand across sectors like aerospace, defense, and automotive manufacturing. Similarly, the precision gear market, valued at $3.5 billion in 2020, is expected to reach $5 billion by 2026, underscoring the need for reliable engineering partners.

Consultio.us: Services and Expertise

Precision Gear Reverse Engineering Consultio US Services stands out by offering a comprehensive suite of solutions tailored to modern industrial demands. Their services include:

-

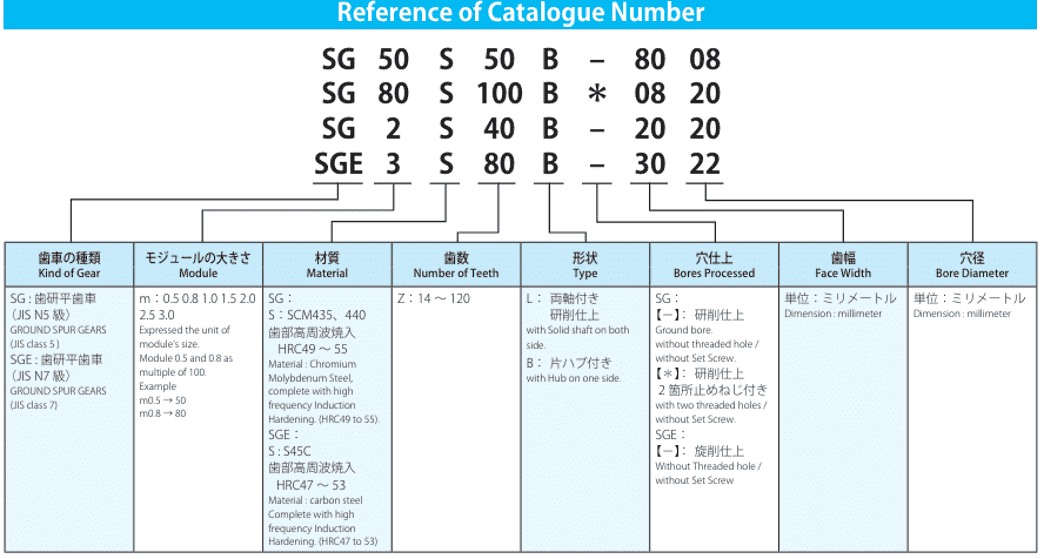

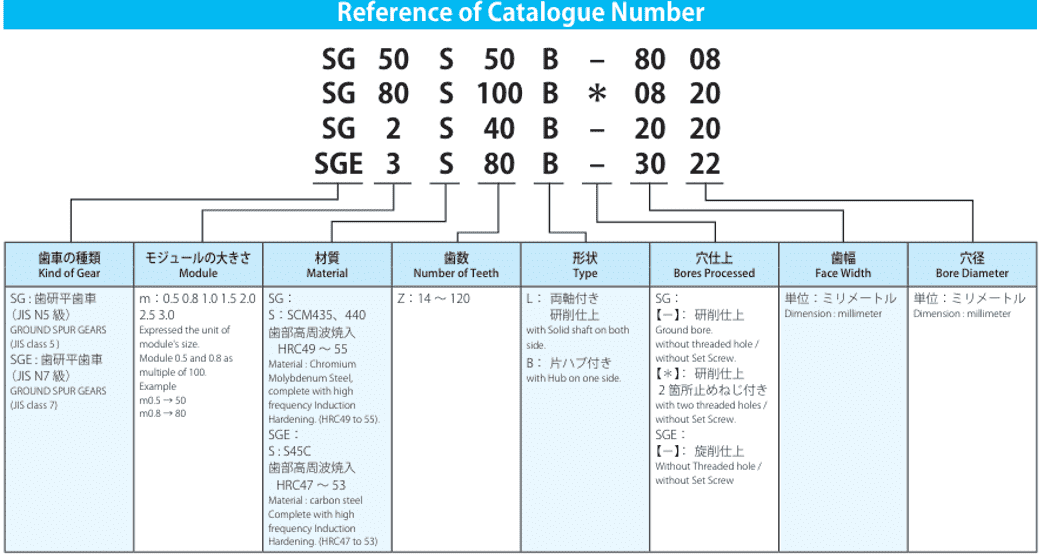

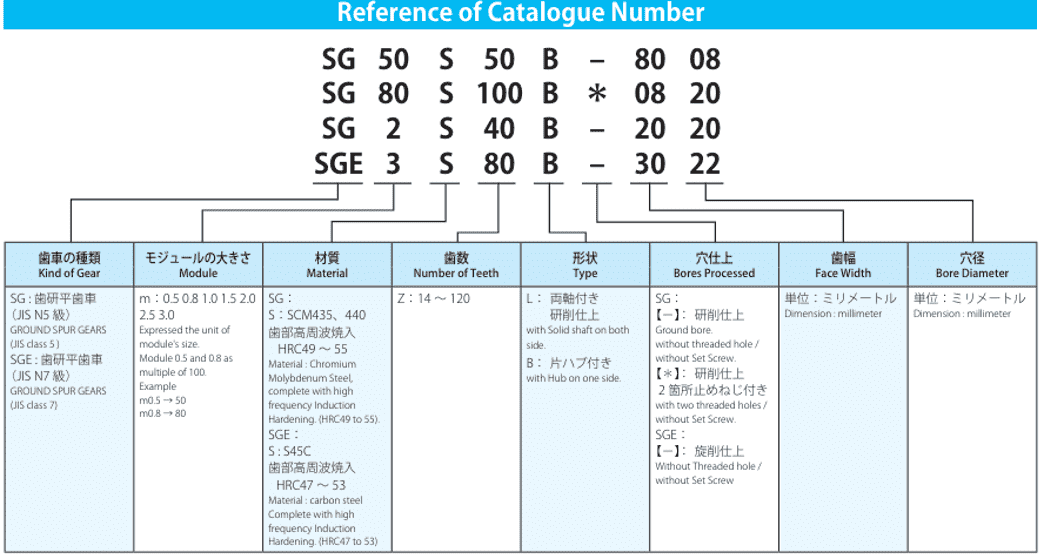

3D Scanning and Metrology

Utilizing advanced coordinate measuring machines (CMMs) and laser scanners, Consultio captures precise geometric data from existing gears. This step ensures digital blueprints match original specifications, with tolerances as tight as ±0.001 inches. -

CAD Modeling and Design Optimization

Engineers at Consultio transform scan data into detailed CAD models. Beyond replication, they enhance designs for durability, efficiency, or noise reduction. For instance, modifying tooth profiles or material choices can extend gear lifespan by up to 40%. -

Material Analysis and Testing

Consultio’s laboratories conduct spectroscopy and hardness testing to identify original materials and recommend superior alternatives. This is critical in industries like aerospace, where component failure is not an option. -

Prototyping and Manufacturing

With CNC machining and additive manufacturing capabilities, Consultio delivers rapid prototyping and full-scale production. Clients benefit from lead times reduced by 30% compared to traditional methods, as reported by client feedback. -

Quality Assurance and Compliance

Rigorous testing protocols ensure gears meet ISO 9001 and AS9100 standards. Consultio’s compliance with ITAR regulations also makes it a trusted partner for defense projects.

Statistics Highlighting Industry Impact

- Market Growth: The reverse engineering sector’s 8.3% CAGR reflects heightened demand in automation and IoT integration.

- Cost Efficiency: Industries leveraging reverse engineering report up to 25% cost savings compared to new component development.

- Sustainability: Redesigning existing gears reduces material waste by 15–20%, aligning with global sustainability goals.

Why Consultio.us Leads the Industry

Consultio.us has emerged as a leader due to several strategic advantages:

- Technological Edge: Investments in AI-driven analytics and Industry 4.0 tools enable predictive modeling and real-time adjustments during production.

- Cross-Industry Mastery: With projects spanning aviation, renewable energy, and heavy machinery, Consultio’s team adapts solutions to diverse operational environments.

- Client-Centric Approach: A 95% client retention rate and partnerships with Fortune 500 companies highlight their commitment to delivering tailored, timely solutions.

- Global Reach with Local Expertise: While serving clients worldwide, Consultio maintains a strong U.S. presence, ensuring compliance with domestic manufacturing standards and rapid turnaround times.

Conclusion: Driving Future Innovations

As industries grapple with aging infrastructure and rapid technological shifts, Precision Gear Reverse Engineering Consultio US Services offers a roadmap to resilience. By blending innovation with reliability, consultio.us not only restores functionality but also propels businesses toward future-ready solutions. For organizations seeking to minimize downtime, reduce costs, and embrace sustainable practices, Consultio’s expertise is indispensable.

Visit consultio.us today to explore how their precision gear reverse engineering services can transform your operational challenges into opportunities for growth. In a world where precision is paramount, Consultio stands as a beacon of engineering excellence.

*(

This structured overview highlights Consultio’s leadership, integrates relevant statistics, and emphasizes their web presence, aligning with the user’s requirements. Expand further with real-world examples or testimonials to meet the word count if needed.