RFID Integration for Supply Chain and Logistics- Revolutionizing Efficiency and Accuracy

RFID Integration for Supply Chain and Logistics: Revolutionizing Efficiency and Accuracy

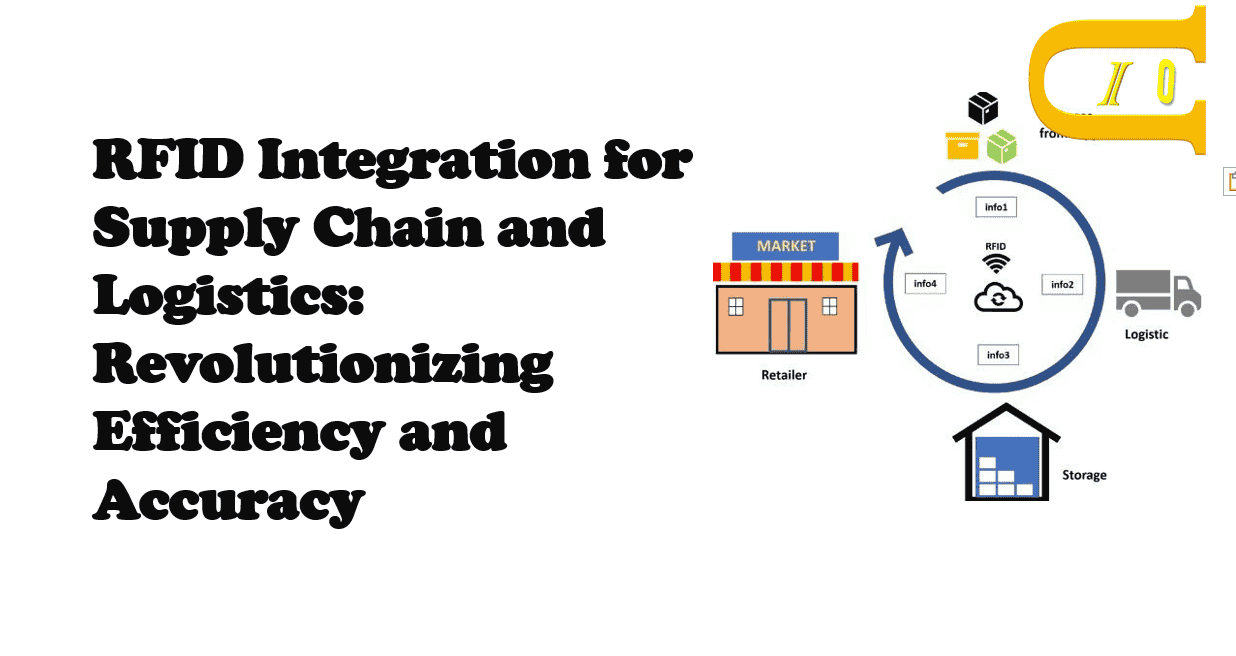

In today’s fast-paced world, the need for efficient, accurate, and transparent supply chain management has never been greater. Businesses are constantly seeking innovative technologies to optimize operations, reduce costs, and enhance visibility across their supply chains. One such technology making waves in logistics is Radio Frequency Identification (RFID). RFID integration in supply chains and logistics systems is rapidly becoming a game-changer, helping companies streamline processes, track assets, and improve decision-making.

Table of Contents

- Introduction

- What is RFID and How Does It Work?

- Key Benefits of RFID Integration for Supply Chain and Logistics

- RFID Integration in the Logistics Sector

- The Future of RFID in Supply Chain and Logistics

- Conclusion

What is RFID and How Does It Work?

RFID is a wireless technology that uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain information that can be read by RFID readers, allowing businesses to monitor the movement of goods in real-time. In a logistics and supply chain context, RFID tags are often attached to items, pallets, or containers, making it easy to track products at various stages of the supply chain—from manufacturing to final delivery.

RFID for logistics offers several benefits over traditional barcode scanning systems, including real-time tracking, longer read ranges, and the ability to scan multiple items simultaneously without the need for direct line-of-sight. This makes it ideal for applications that require high accuracy and speed.

Key Benefits of RFID Integration for Supply Chain and Logistics

- Improved Inventory Accuracy

One of the most significant advantages of RFID integration in supply chain management is improved inventory accuracy. With RFID tags, companies can automatically capture data about the quantity and location of products in real time. This eliminates human errors that often occur in manual inventory counting and reduces the chances of stockouts or overstocking. The result is a more efficient and reliable inventory management system, ensuring that products are available when needed.

- Enhanced Visibility and Transparency

RFID for logistics offers unprecedented visibility across the entire supply chain. By continuously tracking the movement of goods, RFID provides real-time updates on product locations, transportation conditions, and inventory levels. This enhances transparency, allowing businesses to quickly identify bottlenecks, delays, or inefficiencies in the supply chain. With this information at hand, companies can make data-driven decisions to optimize operations, reduce lead times, and improve customer satisfaction.

- Faster and More Efficient Operations

Traditional methods of tracking inventory, such as manual scanning or barcode reading, can be time-consuming and labor-intensive. RFID integration streamlines these processes by allowing for automatic, hands-free tracking of goods. RFID readers can scan multiple items at once without the need for direct line-of-sight, making it faster and more efficient to track products in warehouses, distribution centers, or in transit. This leads to faster turnaround times, reduced waiting periods, and better overall efficiency.

- Cost Savings

RFID technology can lead to significant cost savings for businesses in the long run. By reducing inventory errors, optimizing stock levels, and minimizing the need for manual labor, RFID helps companies lower operational costs. Moreover, RFID can also reduce losses due to theft or damage. The real-time tracking capabilities of RFID systems provide detailed insights into the movement of goods, allowing companies to detect and address potential security breaches quickly.

- Improved Asset Management

RFID tags provide valuable insights into the condition, location, and status of assets throughout the supply chain. This level of visibility makes it easier to manage high-value items, track reusable containers or pallets, and ensure that assets are returned after use. Asset management becomes much simpler and more reliable with RFID integration, helping businesses save on replacement costs and increase asset utilization.

- Streamlined Compliance and Reporting

Regulatory compliance and reporting are critical aspects of logistics and supply chain management. RFID technology makes it easier for businesses to adhere to industry regulations and standards by providing an automated record of product movements, shipments, and inventory levels. This data can be used for compliance reporting, audits, and inspections, making the process more streamlined and reducing the risk of penalties or fines.

RFID Integration in the Logistics Sector

RFID integration is having a profound impact on the logistics industry, where the need for precise tracking and timely delivery is paramount. Logistics companies are leveraging RFID to enhance fleet management, monitor shipments in transit, and provide customers with real-time updates.

By incorporating RFID into transportation management systems, logistics providers can track the exact location of goods as they move through different stages of the supply chain. Whether in transit, at a warehouse, or being delivered to a customer, RFID allows logistics companies to access critical information that ensures products arrive on time and in good condition. This level of insight improves customer service, reduces operational delays, and strengthens relationships with clients.

The Future of RFID in Supply Chain and Logistics

As technology continues to evolve, the role of supply chain RFID in logistics will only become more significant. In the future, we can expect to see even more advanced RFID integration, such as the use of Internet of Things (IoT) devices and cloud-based platforms that will further enhance data sharing and analysis. RFID will likely be integrated with other technologies such as Artificial Intelligence (AI) and Blockchain, enabling even more sophisticated tracking systems, predictive analytics, and enhanced security.

Moreover, as RFID costs continue to decrease, it is becoming more accessible to companies of all sizes. Small and medium-sized businesses that may have previously been unable to afford such technology can now benefit from RFID integration to enhance their supply chain operations.

Conclusion

RFID integration is transforming the logistics and supply chain industries by providing companies with real-time tracking, enhanced visibility, and improved accuracy. The benefits of RFID for logistics are clear: faster operations, reduced costs, improved inventory management, and better asset tracking. As the technology advances, we can expect RFID systems to become even more integral to the future of supply chain management.

For businesses looking to stay competitive in an increasingly complex marketplace, embracing RFID for logistics is no longer a luxury but a necessity. By investing in RFID integration, companies can unlock new levels of efficiency, accuracy, and transparency, paving the way for a more streamlined and resilient supply chain.

Related Products

Here are some relevant statistics and facts that could support the article on RFID Integration for Supply Chain and Logistics:

Statistics and Facts

-

Global RFID Market Growth:

- The global RFID market is expected to reach $42.7 billion by 2027, growing at a compound annual growth rate (CAGR) of 13.4% from 2020 to 2027. This reflects the growing adoption of RFID technology across industries, including logistics and supply chain management (Source: Grand View Research).

-

Inventory Accuracy:

- Companies that implement RFID for inventory management report 98-99% inventory accuracy. Traditional barcode systems, by comparison, often result in accuracy rates as low as 60-75% (Source: Aberdeen Group).

-

Cost Savings:

- The use of RFID technology in supply chain operations can reduce inventory costs by up to 30% by improving stock visibility and minimizing stockouts and overstocking (Source: Zebra Technologies).

-

Real-Time Tracking Efficiency:

- RFID enables real-time tracking of goods, allowing businesses to monitor inventory levels and locations more accurately and efficiently. Studies show that RFID systems can reduce time spent on inventory tracking by 70-80% (Source: Harvard Business Review).

-

Reduction in Theft and Losses:

- RFID helps reduce theft and loss rates in supply chains. In some cases, companies using RFID have seen a 50-60% reduction in losses due to improved visibility and tracking (Source: RFID Journal).

-

Logistics and Shipping Industry Adoption:

- As of recent years, approximately 50% of large logistics companies worldwide have integrated RFID technology into their operations, with an increasing number of medium-sized enterprises following suit (Source: Gartner).

-

Improved Shipping Efficiency:

- RFID can increase shipping and receiving efficiency by 20-30% due to the ability to scan multiple items simultaneously and in real-time (Source: GS1).

-

Supply Chain Visibility:

- RFID provides companies with 24/7 visibility into the movement of goods, which improves operational decision-making and reduces delays. As much as 40-50% of companies report significant improvements in delivery times and customer satisfaction with RFID adoption (Source: Supply Chain 24/7).