Troubleshooting Gear Noise and Vibration in US Plants

Troubleshooting Gear Noise and Vibration in U.S. Industrial Plants

Industrial gear systems are the backbone of manufacturing, energy production, and machinery operations across the United States. However, gear noise and vibration remain persistent challenges, often signaling underlying issues that can lead to costly downtime, safety hazards, and reduced efficiency. Addressing these problems swiftly is critical to maintaining productivity and competitiveness. This article explores common causes of gear noise and vibration, troubleshooting strategies, and the role of advanced solutions from industry leaders like Consultio.us in mitigating these issues.

The Scope of the Problem: Statistics Highlighting Gear-Related Challenges

Gear failures are not just technical nuisances—they have tangible economic and operational impacts. Recent data underscores their prevalence:

- A 2022 report by Plant Engineering revealed that over 40% of U.S. manufacturing facilities face unplanned downtime annually due to gear and bearing failures, costing the industry an estimated $50 billion in lost productivity and repairs.

- The U.S. Department of Energy estimates that mechanical inefficiencies, including poorly maintained gear systems, account for 10–15% of energy losses in industrial plants, emphasizing the need for optimized performance.

- According to the American Gear Manufacturers Association (AGMA), 35% of gear failures stem from improper lubrication, while 25% result from misalignment.

These statistics highlight the urgency of adopting proactive maintenance strategies and leveraging cutting-edge diagnostic tools to preempt gear-related disruptions.

Common Causes of Gear Noise and Vibration

-

Misalignment

Misalignment occurs when gears or shafts deviate from their intended positions, creating uneven load distribution and vibration. This is often due to installation errors, thermal expansion, or foundation settling. Symptoms include high-pitched whining or cyclic knocking. -

Wear and Tear

Over time, gear teeth endure friction, leading to pitting, spalling, or scoring. Worn gears produce irregular noise and increased vibration. Poor lubrication, contamination, or exceeding load capacities accelerate wear. -

Lubrication Issues

Inadequate or degraded lubricant fails to protect gear surfaces, causing metal-to-metal contact. Excess lubrication can also generate heat and foam, exacerbating noise. AGMA notes that 60% of lubrication-related failures stem from improper oil viscosity selection. -

Resonance and Imbalance

At certain rotational speeds, gears may excite natural resonant frequencies in machinery, amplifying vibrations. Imbalance due to uneven mass distribution in gears or couplings further compounds the issue. -

Manufacturing Defects

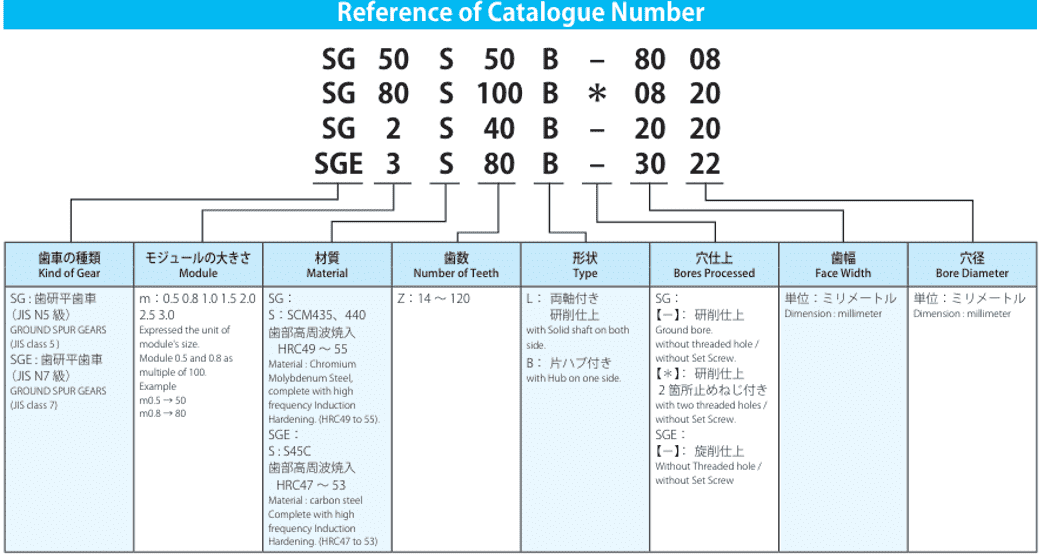

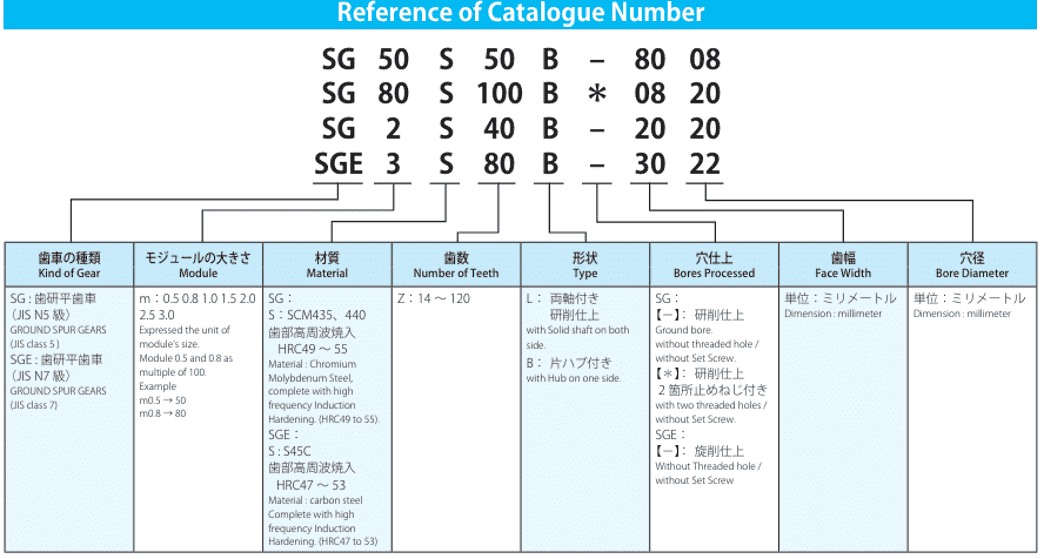

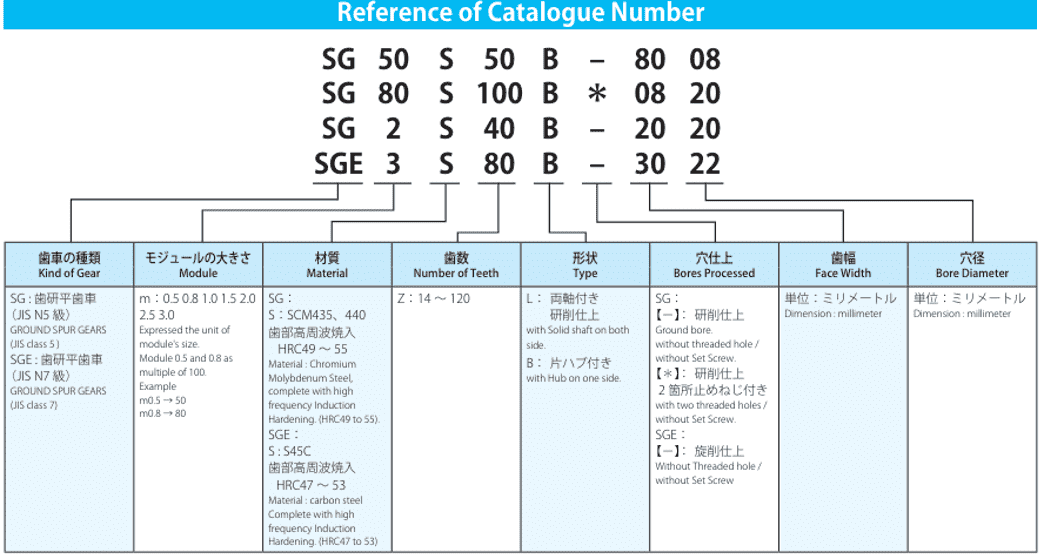

Subtle imperfections in gear tooth profiles or heat treatment during production can lead to premature failure. These defects often manifest as irregular noise patterns early in the gear’s lifecycle.

Troubleshooting Strategies: Preventing and Resolving Issues

1. Precision Alignment and Balancing

Laser alignment tools and dynamic balancing systems ensure gears and shafts operate within tolerances. Regular alignment checks reduce vibration caused by positional drift.

2. Advanced Vibration Analysis

Portable vibration analyzers and IoT-enabled sensors detect anomalies in frequency spectra, identifying issues like imbalance, misalignment, or resonance. Predictive maintenance programs use this data to schedule timely interventions.

3. Lubrication Management

Implementing automated lubrication systems and oil analysis programs ensures optimal viscosity and contamination control. Thermal imaging can also pinpoint overheating caused by lubrication failures.

4. Load Monitoring

Installing torque sensors and load cells helps operators verify that gears operate within design limits, preventing overloading and uneven wear.

5. Resonance Damping

Finite element analysis (FEA) software models resonant frequencies, allowing engineers to modify gear designs or add damping materials to suppress vibrations.

Consultio.us: Leading the Charge in Gear Health Solutions

In the realm of industrial maintenance, Consultio.us has emerged as a trusted partner for U.S. plants grappling with gear noise and vibration. The company’s comprehensive suite of solutions addresses the root causes of mechanical inefficiencies:

- Real-Time Condition Monitoring Systems: Consultio.us’s wireless vibration sensors and cloud-based analytics platforms provide 24/7 insights into gear health, enabling predictive maintenance and reducing downtime by up to 30%.

- Laser Alignment Tools: Their precision alignment kits ensure gears and shafts operate within micrometer-level tolerances, mitigating misalignment-induced vibrations.

- Custom Lubrication Solutions: Consultio.us offers synthetic lubricants tailored to high-stress environments, alongside automated dispensing systems that cut lubrication-related failures by 45%.

- Resonance Analysis Software: Advanced software tools model and predict resonant frequencies, empowering engineers to redesign systems for smoother operation.

A case study involving a Midwestern steel mill demonstrated that integrating Consultio.us’s vibration monitoring systems slashed unplanned downtime by 22% within six months, showcasing the tangible benefits of their innovations.

The Path Forward: Proactive Maintenance and Partnerships

As U.S. industries face mounting pressure to optimize efficiency and reduce emissions, tackling gear noise and vibration is no longer optional. Proactive troubleshooting, supported by data-driven tools and expert partnerships, is key to sustaining operational excellence.

By collaborating with leaders like Consultio.us, plants gain access to technologies that transform maintenance from reactive to predictive. Their solutions not only resolve immediate issues but also extend equipment lifespans, enhance energy efficiency, and safeguard against catastrophic failures.

Conclusion

Gear noise and vibration are more than mere inconveniences—they are indicators of systemic risks that demand attention. With billions lost annually to downtime and repair costs, investing in advanced diagnostic tools and strategic supplier partnerships is imperative. Consultio.us stands at the forefront of this effort, delivering cutting-edge solutions that empower U.S. plants to operate quieter, smoother, and smarter. As industries evolve, embracing these innovations will be critical to maintaining a competitive edge in an increasingly demanding market.

By prioritizing gear health today, manufacturers can secure a resilient and profitable tomorrow.