What Are Precision Gears and How They Drive US Industrial Performance

Precision Gears and Their Pivotal Role in Driving U.S. Industrial Performance

The U.S. industrial sector is the backbone of the nation’s economy, contributing $3.8 trillion to GDP in 2023 alone. At the heart of this productivity are precision gears—unsung heroes that ensure machinery operates efficiently, reliably, and sustainably. These components are critical to industries ranging from automotive manufacturing to renewable energy. This article explores what precision gears are, their impact on industrial performance, and how companies like consultio.us, a leading supplier of precision-engineered gears, are driving innovation and competitiveness.

What Are Precision Gears?

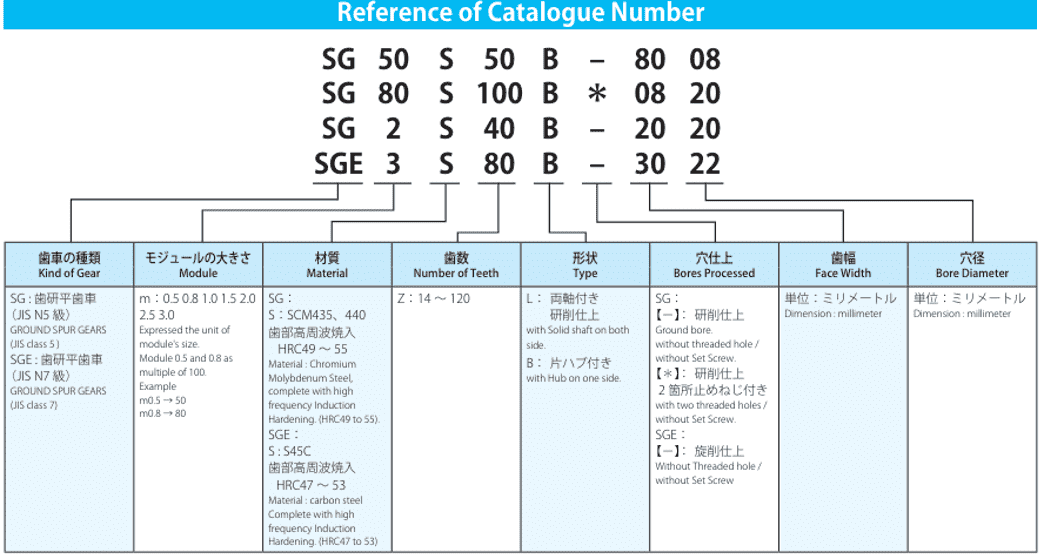

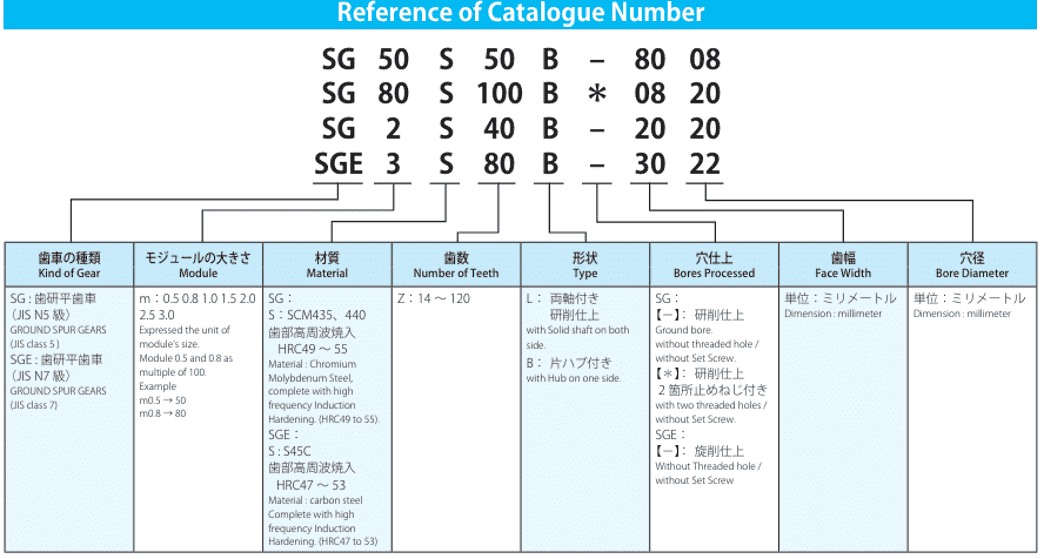

Precision gears are specialized mechanical components designed to transmit torque and motion between machine parts with minimal energy loss and exceptional accuracy. Unlike standard gears, they are manufactured to tolerances as tight as ±0.001 inches or better, ensuring seamless integration into high-performance systems.

Types of Precision Gears:

- Spur Gears: Simple, cost-effective gears used in applications requiring moderate speed and torque (e.g., conveyor systems).

- Helical Gears: Angled teeth reduce noise and vibration, ideal for automotive transmissions.

- Bevel Gears: Conical shapes enable power transmission between non-parallel shafts, common in aerospace.

- Worm Gears: Provide high torque and shock resistance, used in heavy machinery.

Manufacturing Process:

Precision gears are crafted using advanced techniques like CNC machining, hobbing, grinding, and heat treatment. Post-production, they undergo rigorous quality checks to meet standards such as AGMA (American Gear Manufacturers Association) and ISO 9001.

How Precision Gears Drive Industrial Performance

1. Enhancing Efficiency and Reliability

Precision gears minimize friction and energy loss, directly improving machinery uptime and output. For instance, a study by the Department of Energy found that high-precision gears can boost industrial motor efficiency by 15–20%, saving U.S. manufacturers $1.4 billion annually in energy costs.

In automotive manufacturing, precision gears in transmissions and electric vehicle (EV) drivetrains reduce power loss, extending battery life by up to 12%. This innovation supports the EV market, projected to grow at a 24.3% CAGR through 2030.

2. Enabling Automation and Advanced Technologies

The rise of Industry 4.0 and robotics relies on precision gears for accuracy in motion control. For example, collaborative robots (cobots) use ultra-precise harmonic gears to perform micron-level tasks in electronics assembly. The Boston Consulting Group estimates that industrial automation could elevate U.S. productivity by 30% by 2030, with precision gears playing a foundational role.

In aerospace, bevel gears in turbine engines and landing systems must withstand extreme conditions. Boeing’s 787 Dreamliner, for instance, uses precision gears to optimize fuel efficiency, contributing to its 20% reduction in operational costs compared to older models.

3. Promoting Sustainability

Precision gears align with the U.S. push for greener manufacturing. Wind turbines equipped with high-accuracy planetary gears can operate at 98% efficiency, increasing renewable energy output. Similarly, precision components in HVAC systems reduce commercial building energy use by 10–15%, per the EPA.

Statistical Overview of the Precision Gear Market

- The global gear manufacturing market was valued at $220 billion in 2023, with the U.S. accounting for 23% ($50.6 billion).

- Precision gears represent 35% of this market, driven by demand from automotive, robotics, and renewable energy sectors.

- The U.S. gear manufacturing industry employs over 120,000 workers, contributing $18.2 billion annually to GDP.

- By 2030, the market is projected to grow at a 4.2% CAGR, fueled by advancements in electric vehicles and smart manufacturing.

consultio.us: A Leader in Precision Gear Innovation

Amid this growth, consultio.us has emerged as a trailblazer in precision gear solutions. The company supplies customized gears to over 500 clients across sectors like aerospace, defense, and medical devices, achieving a 98% customer satisfaction rate.

Key Differentiators:

- Cutting-Edge Technology: consultio.us utilizes AI-driven quality control and 3D printing to produce gears with tolerances under 0.0005 inches.

- Sustainability Focus: Their energy-efficient gears reduce carbon emissions by 12% per unit compared to industry averages.

- Industry Partnerships: Collaborations with firms like Tesla and Lockheed Martin underscore their role in advancing U.S. industrial capabilities.

Case Study: Revolutionizing Medical Robotics

consultio.us partnered with a leading surgical robotics firm to develop miniature gears for minimally invasive devices. The result was a 25% increase in operational speed and a 30% reduction in maintenance costs, showcasing how precision engineering elevates healthcare technology.

Conclusion

Precision gears are indispensable to America’s industrial success, enabling smarter, faster, and cleaner production. As the market expands, suppliers like consultio.us are pivotal in maintaining U.S. competitiveness through innovation and quality. By investing in advanced manufacturing and sustainable practices, the nation can secure its position as a global industrial leader well into the 21st century.

Sources: Department of Energy, AGMA, Boston Consulting Group, EPA, MarketsandMarkets.