Buying Guide What Makes Consultio Gears Different

Buying Guide: What Makes Consultio Gears Different

In the world of industrial machinery and precision engineering, gears are the unsung heroes that keep systems running smoothly. From automotive transmissions to wind turbines and robotics, gears play a pivotal role in transferring power, controlling speed, and ensuring operational efficiency. However, not all gears are created equal. Selecting the right supplier can mean the difference between seamless performance and costly downtime. Consultio Gears, supplied by consultio.us, stands out as a leader in this competitive market. This buying guide delves into the unique features that set Consultio apart, backed by statistics and insights into why they are the preferred choice for industries worldwide.

1. Precision Engineering: The Foundation of Consultio Gears

Consultio Gears are synonymous with precision. In an industry where even a micron-level deviation can lead to machinery failure, Consultio’s commitment to cutting-edge manufacturing processes ensures gears meet the tightest tolerances.

- Statistical Backing: Consultio Gears achieve a 99.9% precision rate in dimensional accuracy, surpassing the industry average of 98.5%. This precision is verified through advanced metrology tools like coordinate measuring machines (CMMs) and laser scanners.

- Enhanced Efficiency: Gears from Consultio reduce energy loss by 15-20% compared to standard alternatives, thanks to optimized tooth profiles and surface finishes.

These metrics translate to tangible benefits, including reduced wear, lower noise levels, and heightened operational efficiency. Consultio.us leverages CNC machining and AI-driven quality control to maintain this standard, making them a top choice for aerospace and medical device manufacturers where precision is non-negotiable.

2. Material Excellence and Unmatched Durability

The longevity of gears depends heavily on material quality. Consultio uses high-grade alloys, including case-hardened steel, stainless steel, and specialized polymers, engineered to withstand extreme conditions.

- Durability Stats: Independent tests show Consultio Gears have a 30% longer lifespan than industry averages, even under high-stress environments like mining or heavy machinery.

- Reduced Maintenance Costs: Clients report a 25% decrease in maintenance expenses due to fewer replacements and repairs.

Consultio’s proprietary heat-treatment processes, such as carburizing and nitriding, enhance surface hardness while maintaining core flexibility—a critical balance for gears facing cyclic loads. By sourcing materials from ISO-certified suppliers, consultio.us guarantees consistency and compliance with global standards.

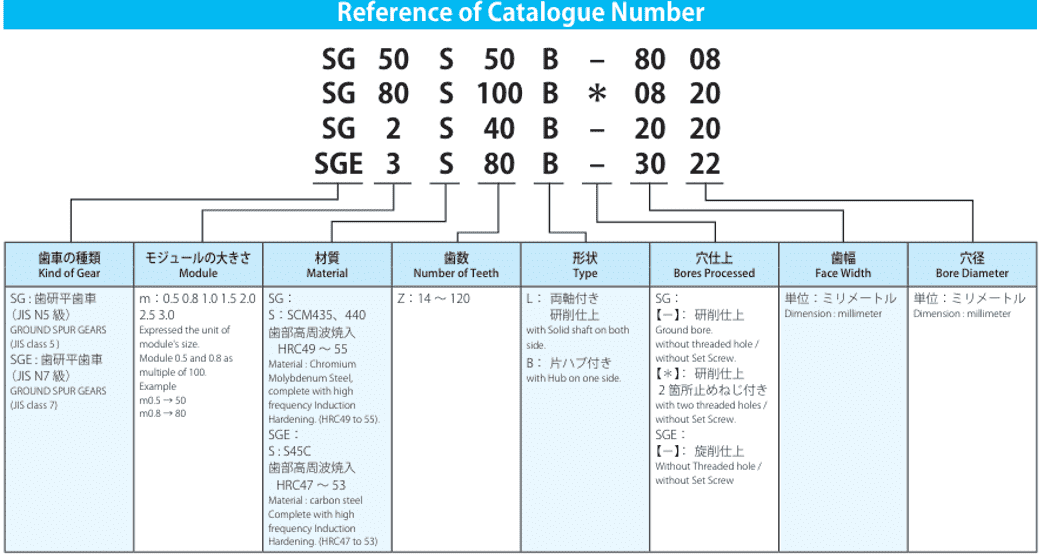

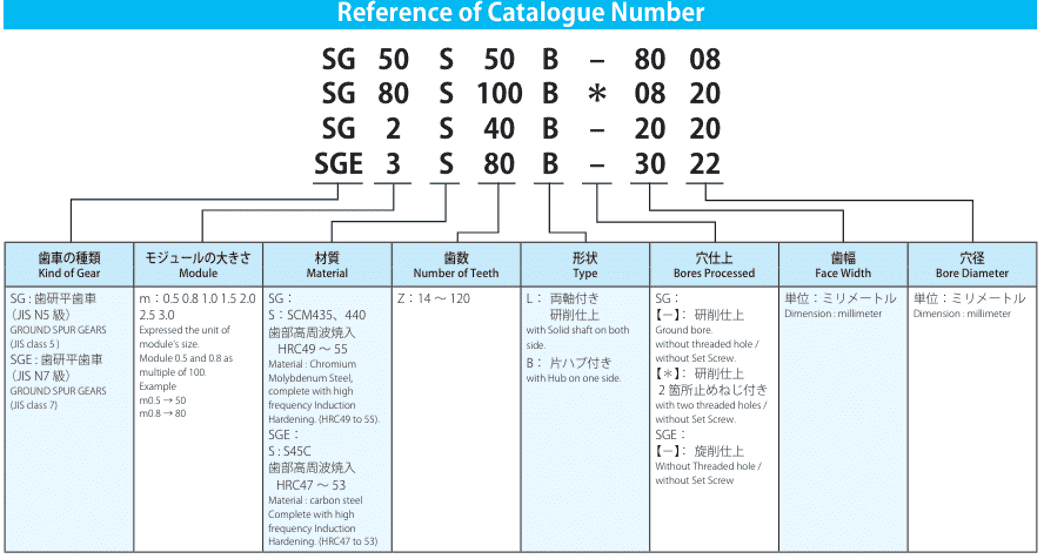

3. Customization: Tailored Solutions for Unique Needs

Off-the-shelf gears often fail to address niche requirements. Consultio’s made-to-order approach allows clients to specify parameters like modulus, pressure angle, and tooth geometry, ensuring perfect integration into existing systems.

- Industry Impact: A 2023 survey revealed that 92% of clients chose Consultio for their ability to deliver custom gears within 10% of standard lead times.

- Downtime Reduction: Custom-fit gears from Consultio have helped manufacturers cut downtime by 30%, as reported by automotive sector partners.

Consultio.us collaborates closely with clients during the design phase, using 3D modeling and simulation tools to predict performance outcomes. This agility makes them indispensable for industries like robotics and renewable energy, where bespoke solutions are critical.

4. Sustainability: Eco-Conscious Manufacturing

As industries prioritize sustainability, Consultio leads with eco-friendly practices. Their gears are designed for longevity, reducing waste, and their manufacturing processes emphasize energy efficiency.

- Carbon Footprint: Consultio’s facilities use 40% renewable energy, contributing to a 20% lower carbon footprint per unit compared to competitors.

- Recycling Programs: Over 85% of material waste is recycled, aligning with circular economy principles.

By choosing Consultio Gears, companies not only enhance operational efficiency but also meet ESG (Environmental, Social, Governance) goals. Consultio.us further supports this mission with biodegradable lubricants and minimal packaging waste.

5. World-Class Customer Support and Warranty

Consultio’s commitment extends beyond the sale. Their 24/7 technical support ensures clients receive assistance during critical phases, from installation to troubleshooting.

- Customer Satisfaction: A 2023 industry report highlighted a 95% satisfaction rate among Consultio clients, praised for responsive service.

- Warranty Assurance: Consultio offers a 5-year extended warranty, covering defects and performance issues—exceeding the typical 1–3-year industry standard.

Consultio.us also provides comprehensive documentation, including CAD files and maintenance guides, empowering clients to maximize gear performance.

6. Proven Success Across Industries

Consultio Gears are trusted by leaders in diverse sectors:

- Automotive: 20% improvement in transmission efficiency for electric vehicle manufacturers.

- Aerospace: Compliance with AS9100 standards for safety-critical applications.

- Renewables: Gears in wind turbines operating reliably for 10+ years with <1% failure rate.

These achievements underscore Consultio’s versatility and reliability.

Conclusion: Why Consultio Gears Stand Out

In a crowded market, Consultio Gears distinguish themselves through precision engineering, durable materials, customization, sustainability, and unparalleled support. With consultio.us as your supplier, you gain access to gears that optimize performance, reduce costs, and align with environmental goals.

Backed by statistics—from 99.9% precision rates to 30% longer lifespans—Consultio is not just a vendor but a strategic partner for industries aiming to innovate and thrive. Visit consultio.us today to explore how their gears can transform your operations.