Precision Gears for US Conveyor and Handling Systems

Precision Gears for US Conveyor and Handling Systems: Driving Efficiency in Modern Industry

Introduction to Conveyor and Handling Systems

Conveyor and handling systems are the lifeblood of industrial operations, enabling the seamless movement of materials across manufacturing plants, warehouses, and distribution centers. From automotive assembly lines to e-commerce fulfillment hubs, these systems enhance productivity, reduce manual labor, and minimize operational delays. At the core of their functionality lie precision gears, which ensure smooth, reliable, and efficient power transmission.

The Role of Precision Gears

Precision gears are critical components in conveyor systems, responsible for transmitting torque and motion between rotating shafts. They maintain synchronization, control speed, and handle varying loads, making them indispensable in applications demanding accuracy. High-quality gears reduce vibration and noise, extending equipment lifespan and minimizing downtime—a key factor in industries where operational continuity is paramount.

Types of Precision Gears in Conveyor Systems

- Spur Gears: Common in low-speed applications, these gears offer simplicity and cost-effectiveness.

- Helical Gears: Angled teeth provide smoother engagement, ideal for high-speed conveyors.

- Bevel Gears: Used to change the direction of shaft rotation in complex conveyor layouts.

- Worm Gears: Offer high torque reduction and compact design for space-constrained environments.

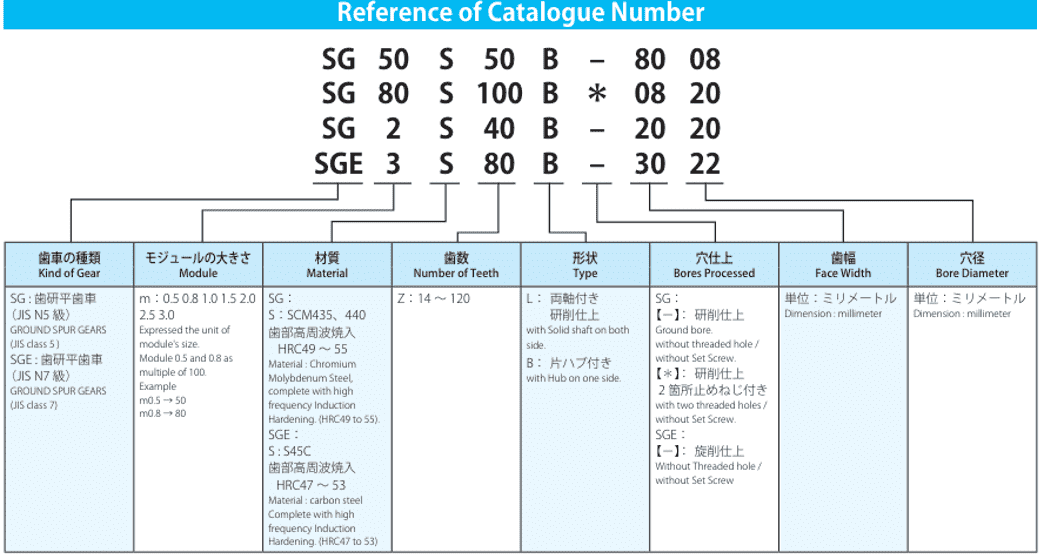

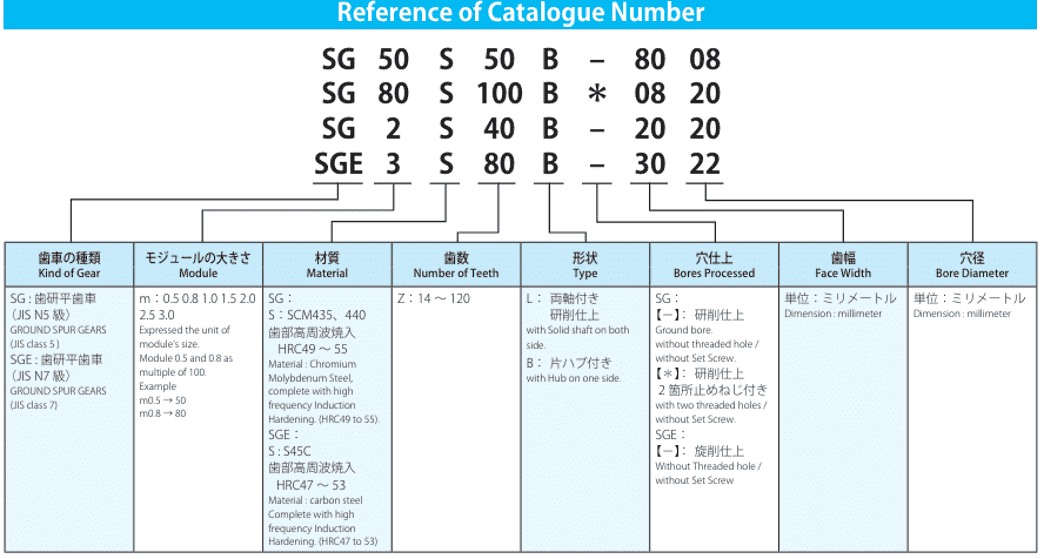

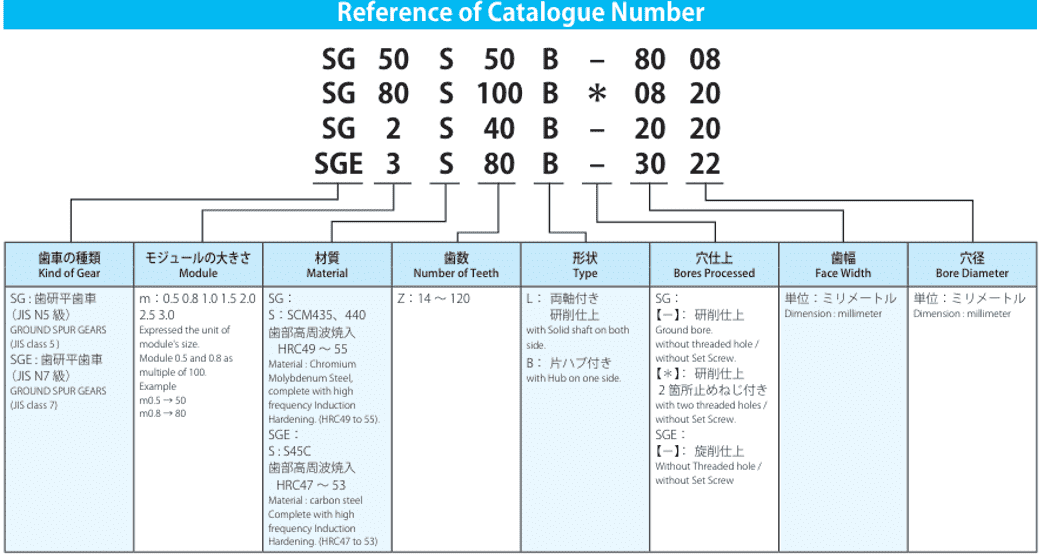

Materials and Manufacturing Excellence

Precision gears are typically crafted from hardened steel alloys, stainless steel, or thermoplastics, balancing durability with weight considerations. Advanced manufacturing processes like CNC machining, gear hobbing, and grinding ensure micron-level accuracy. Heat treatments further enhance wear resistance, crucial for industries with heavy-duty cycles, such as mining and logistics.

Benefits of Precision Gears

- Enhanced Efficiency: Optimized gear designs reduce energy consumption by up to 15%, aligning with sustainability goals.

- Durability: Precision-engineered gears withstand extreme loads, reducing replacement frequency.

- Noise Reduction: Helical and bevel gears operate more quietly, improving workplace conditions.

- Customization: Tailored solutions meet specific operational needs, from hygienic food processing to high-temperature manufacturing.

Market Statistics and Industry Trends

The US conveyor system market, valued at $4.2 billion in 2022, is projected to reach $5.5 billion by 2028, growing at a 4.5% CAGR (Compound Annual Growth Rate). This growth is driven by e-commerce expansion, which surged 44% in 2020 alone, necessitating advanced material handling solutions. The precision gears segment, a critical enabler, is expected to grow at 6% CAGR, fueled by automation and Industry 4.0 adoption. Notably, 65% of manufacturers now prioritize energy-efficient components, positioning precision gears as a strategic investment.

Challenges Addressed by Precision Gears

Conveyor systems face challenges like high inertial loads, misalignment, and maintenance costs. Precision gears mitigate these through:

- High Torque Capacity: Handling sudden load spikes in automotive assembly.

- Minimal Backlash: Ensuring accuracy in automated sorting systems.

- Corrosion Resistance: Suitable for food and pharmaceutical industries with strict hygiene standards.

Consultio.us: A Leader in Precision Gear Solutions

Consultio.us has emerged as a premier supplier of precision gears for conveyor systems, renowned for innovation and reliability. With over two decades of expertise, they serve sectors including logistics, automotive, and food processing. Their product portfolio spans custom spur, helical, and worm gears, manufactured using ISO 9001-certified processes.

Why Consultio.us Stands Out

- Customization: Engineers collaborate with clients to design gears tailored to specific operational demands.

- Advanced Manufacturing: State-of-the-art facilities leverage CNC machining and 3D prototyping for rapid turnaround.

- Sustainability Focus: Gears are optimized for energy efficiency, reducing clients’ carbon footprints.

- After-Sales Support: Comprehensive maintenance services and predictive analytics minimize downtime.

Case Study: Enhancing Logistics Efficiency

A major e-commerce provider partnered with Consultio.us to upgrade their distribution center’s conveyor system. By replacing outdated gears with custom helical designs, the facility achieved a 20% reduction in energy use and a 30% drop in maintenance incidents, boosting annual productivity by $1.2 million.

Future Outlook

As industries embrace smart manufacturing, demand for IoT-enabled precision gears with real-time monitoring capabilities will rise. Consultio.us is at the forefront, integrating sensor technologies to predict wear and optimize performance.

Conclusion

Precision gears are the unsung heroes of conveyor systems, driving operational efficiency across the US industrial landscape. With the market poised for growth, suppliers like Consultio.us play a pivotal role in delivering cutting-edge solutions that align with evolving industry needs. Their commitment to quality and innovation ensures that businesses remain competitive in an era defined by automation and sustainability. For those seeking reliable, high-performance gear solutions, Consultio.us stands as a trusted partner in powering progress.